Optimizing Performance: Commercial Refrigeration Fixing Techniques for Cost-Effective Solutions

Assessing Refrigeration System Performance

To effectively assess the efficiency of a commercial refrigeration system, it is important to carry out extensive analyses of its vital parts and operational specifications. The very first action in evaluating system performance is examining the capability of the compressor. The compressor plays an important duty in preserving the preferred temperature within the refrigeration unit. Problems with the compressor can lead to poor air conditioning, temperature level changes, and increased energy consumption. Performing routine assessments and performance examinations on the compressor can assist recognize possible problems beforehand and stop pricey break downs.

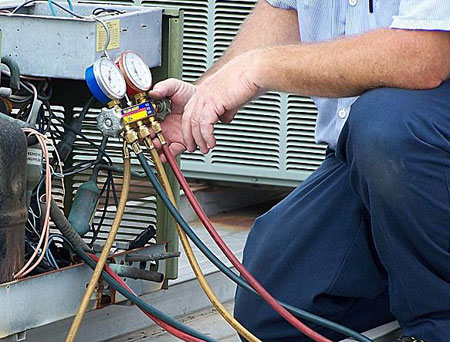

Additionally, evaluating the condenser and evaporator coils is paramount. Clogged up or dirty coils can dramatically influence the system's performance by preventing warm transfer processes. Cleaning the coils routinely and guaranteeing correct airflow around them can optimize the system's cooling capability and decrease energy usage. Keeping track of cooling agent degrees and pressures is also important in examining system efficiency. Low refrigerant levels or abnormal pressures can suggest leaks or malfunctioning elements that need prompt interest to prevent system failures and costly repair services. By methodically evaluating these functional criteria and vital parts, organizations can guarantee their business refrigeration systems operate at peak efficiency levels, minimizing downtime and making the most of power efficiency.

Carrying Out Preventative Upkeep Procedures

Assessing the performance of a commercial refrigeration system offers beneficial insights that can notify the execution of preventative maintenance procedures vital for sustaining optimum functionality and longevity. Preventative maintenance is a positive method intended at determining and attending to prospective problems prior to they intensify into expensive troubles that interfere with procedures. By establishing a normal upkeep timetable, refrigeration systems can operate successfully, minimizing power intake and lessening the risk of unforeseen malfunctions. Trick preventative maintenance actions consist of cleansing and evaluating condenser coils, checking cooling agent degrees, guaranteeing proper airflow, and adjusting temperature controls. Additionally, keeping track of temperature and moisture degrees, checking door seals, and addressing any type of unusual sounds or smells promptly are important action in preventative upkeep. Carrying out these actions not only extends the life-span of the tools however also improves food safety and security by keeping regular storage temperatures. Inevitably, buying preventative upkeep measures is an economical strategy that assists companies avoid costly fixings and downtime, ensuring trusted and constant refrigeration system efficiency.

Identifying Common Refrigeration Issues

Among the essential elements in keeping business refrigeration systems is immediately determining common find out here now problems that might emerge throughout their operation. One prevalent trouble is inadequate air conditioning, frequently triggered by unclean condenser coils or a malfunctioning compressor. Routine cleaning of the condenser coils and making sure correct air flow around the system can assist avoid this concern. Another typical issue is refrigerant leakages, which can cause inefficient cooling and prospective environmental risks. Keeping track of refrigerant levels and performing routine inspections for leaks can help alleviate this trouble. Furthermore, damaged gaskets on doors, causing air leaks, can create the refrigeration system to function more challenging to preserve the desired temperature level. Routine evaluation and replacement of harmed gaskets are vital to prevent power waste. Unusual noises such as banging, clanking, or hissing could indicate underlying why not try this out mechanical concerns that need immediate interest to protect against further damages. By immediately determining and addressing these usual refrigeration concerns, companies can make certain the effective operation of their systems and lessen costly repairs.

Utilizing Energy-Efficient Repair Service Methods

When taking into consideration commercial refrigeration fixing, applying energy-efficient methods is paramount to optimizing the system's performance and decreasing functional costs. Among the essential strategies in accomplishing energy performance is making certain that the refrigeration system is effectively maintained. Normal upkeep, such as cleaning up condenser coils, checking for refrigerant leakages, and adjusting temperature settings, can dramatically improve power effectiveness.

Another energy-efficient fixing strategy is updating to high-efficiency elements - commercial refrigeration repair. By replacing older, less efficient get rid of energy-efficient choices, such as ECM follower electric motors or LED lights, services can lower power consumption and reduced utility prices. Furthermore, mounting programmable thermostats and energy monitoring systems can help control temperature levels better, protecting against unneeded power usage

Furthermore, maximizing the system's insulation and sealing any kind of leakages can likewise add to energy cost savings. Correct insulation aids keep constant temperatures within the refrigeration system, reducing the workload on the system and improving overall efficiency. By including these energy-efficient repair service strategies, companies can not just decrease their ecological influence yet likewise achieve long-term price financial savings.

Optimizing Refrigeration System Life-span

To ensure the longevity and optimum efficiency of business refrigeration systems, maintaining energy-efficient repair methods is crucial, with an emphasis now moving in the direction of making best use of the refrigeration system lifespan. Enhancing the life-span of a refrigeration system includes positive upkeep, timely repair services, and adherence to maker guidelines.

In addition, spending in high-quality parts and parts throughout repairs and replacements can boost the sturdiness of have a peek at this website the refrigeration system. By focusing on aggressive maintenance and making use of quality components, businesses can enhance the lifespan of their business refrigeration systems, ultimately lowering downtime and operational prices.

Conclusion

To conclude, by frequently assessing refrigeration system performance, applying preventative upkeep steps, identifying common refrigeration concerns, making use of energy-efficient fixing strategies, and optimizing the system's life expectancy, services can take full advantage of effectiveness and reduce prices connected with industrial refrigeration repair. These cost-efficient solutions assist to ensure that refrigeration systems operate at peak efficiency, ultimately bring about boosted efficiency and productivity for businesses in the future.

When thinking about commercial refrigeration fixing, implementing energy-efficient strategies is paramount to enhancing the system's performance and reducing functional costs.To make certain the longevity and ideal performance of business refrigeration systems, keeping energy-efficient fixing methods is essential, with an emphasis now moving towards optimizing the refrigeration system life expectancy. Maximizing the life expectancy of a refrigeration system entails proactive maintenance, timely repair work, and adherence to supplier guidelines.